HOME > Saivs brand > hydraulic valves

ZD Hydraulic Directional Control Valves

Function:Directional Control Valve

Spools range:1-3/2-4 spool

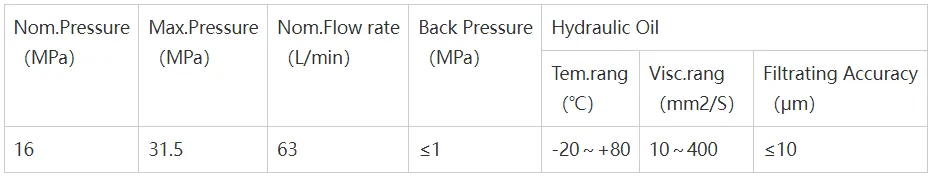

Nom.Pressure(MPa):16

Max.Pressure(MPa):20/31.5

Nom.Flow rate(L/min):40/10.57 GPM,63/16.64 GPM

Back Pressure(MPa): ≤1

Material:Casting Iron

Warranty:1 Year

Drive:Hydraulic

Place of Origin:Ningbo,ZheJi

Minimum Order:

Supply Ability:

Function:Directional Control Valve

Spools range:1-3/2-4 spool

Nom.Pressure(MPa):16

Max.Pressure(MPa):20/31.5

Nom.flow rate(L/min):40/10.57 GPM,63/16.64 GPM

Back Pressure(MPa): ≤1

Material:Casting Iron

Warranty:1 Year

Drive:Hydraulic

Place of Origin:Ningbo,ZheJiang

Customized support:OEM,ODM

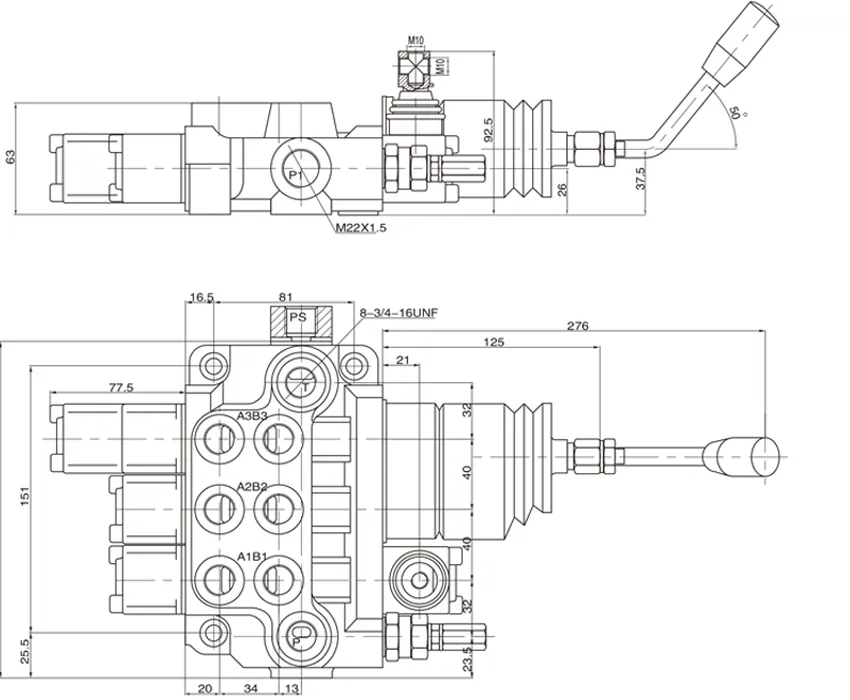

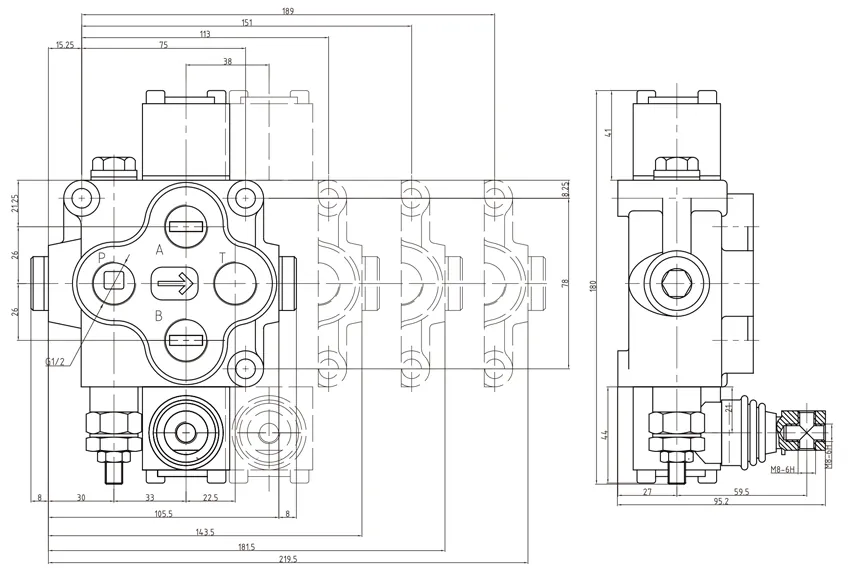

ZD-L15 hydraulic directional control valves

ZD-L15 multi-way Directional Valve is a kind of medium-high pressure integral multi-way directional

valve independently designed and developed by our company. The valve can be installed with overflow valve,

one-way valve, oil filling valve and so on. The overflow valve can adjust the pressure of the system,

the one-way valve can prevent the oil from flowing backward in the armpit, the reversing valve and

the slide valve function can be A, 0, Y, P, etc., which can be arbitrarily combined.

The reversing handle is available in two forms for easy operation in different directions.

The valve USES parallel oil circuit, design a pressure outlet and other hydraulic components to provide power source.

Through the special design sealing way, causes the valve sealing performance to be remarkable.

The valve is widely used in the hydraulic system of engineering machinery

such as forklifts, sanitation vehicles and small loaders.

Feature

monoblock directional control valves has many outstanding features including high performance,

high efficiency, small volume, mass flow, and leak proof.

1.Monoblock types with 2 to 4 working sections

2.Flow 63 l/min with pressure 160bar, 200bar, 315bar

3.Spring side control options: T (spring return) and W (detent control)

4.Joining port: L (screw connection)

5.Parallel circuit

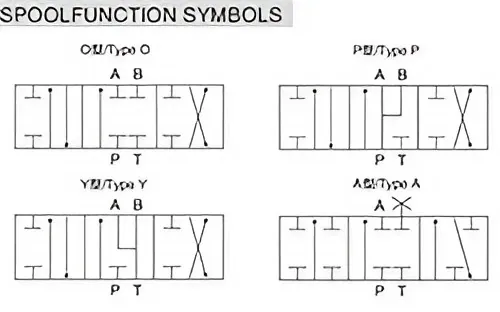

6.Spool function: O, P. Y, A

7.Nominal diameter: G1/2; G3/8; M18*1.5; M22*1.5

8.Model examples: ZD-L15E-2OT; ZD-L15F-2OT.QT etc.

9.Lever side control options: manual, pneumatic control, electric and pneumatic control, micro-switch control.

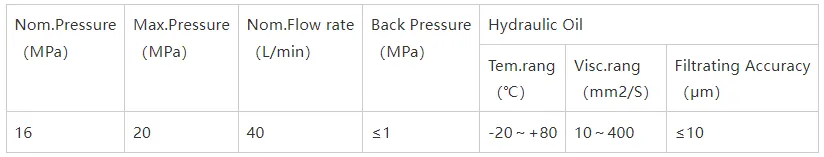

ZD-L102 Hydraulic Directional Control Valves

ZD-L102 multiway directional valve is a kind of medium and high pressure integral multiway directional

valve independently designed and developed by our company. According to customer requirements in the

valve on the overflow valve, one-way valve, etc. Overflow valve can adjust the system pressure,

one-way valve to prevent oil backflow, reversing valve slide valve function A, O, Y, P, etc.,

can be arbitrary combination, reversing handle has two installation forms, easy to operate in different directions,

and the use of parallel oil circuit. Through the special design sealing way, causes the valve sealing

performance to be remarkable. The valve is widely used in forklift, sanitation vehicles,

small loader and other construction machinery hydraulic system.

Inner check valve: The check valve inside the valve body is to insure the hydraulic oil not to bereturned.

lnner relief valve:The relief valve inside the valve body is able to adjust the hydraulic system workingpressure.

Oil way: Parallel circuit

Control Way: Manual control

valve construction: monoblock construction,1-3 levers.Spool Function: O,Y,P.A.

Feature

Monoblock directional control valves has many outstanding features including high performance,

high efficiency, small volume, mass flow, and leak proof.

1.Monoblock types with 1 to 3 working sections

2.Flow 40 l/min with pressure 160bar, 200bar, 250bar

3.Spring side control options: T (spring return) and W (detent control)

4.Joining port: L (screw connection)

5.Parallel circuit

6.Spool function: O, P. Y, A

7.Nominal diameter: G1/2; G3/8; M18*1.5

8.Model examples: ZD-L102E-OT; ZD-L102F-OT.AT; ZD-L102F-OW; ZD-L102E-3OT; ZD-L102-YT.OW.YT etc.

9.Lever side control options: manual

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

Speak to one of our experts today to learn more about our products solutions.