HOME > Saivs brand > hydraulic cylinders

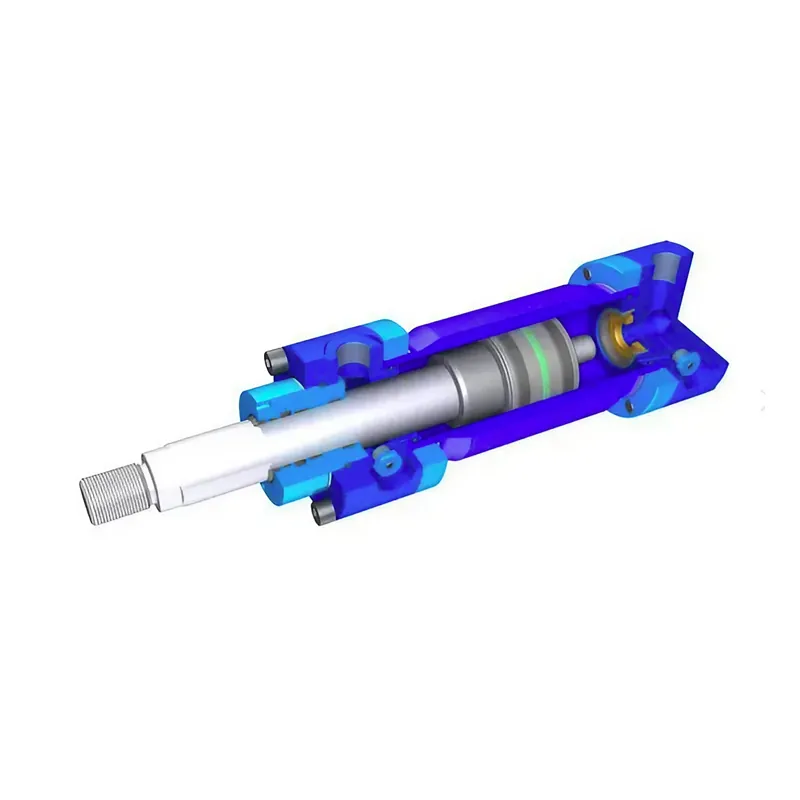

Hydraulic Cylinders for packing machine

Working pressure: Can be customized

Material: Aluminum, Cast Iron, Stainless Steel

Bore Size: 40mm--310mm,Customizable

Shaft Diameter: 20mm--210mm,Customizable

Stroke Length: 30mm--14000mm,Customizable

Color: Customizable

Application: Packing Machinery

Minimum Order:1 Pieces

Minimum Order:

Supply Ability:

Working pressure: Can be customized

Material: Aluminum, Cast Iron, Stainless Steel

Bore Size: 40mm--310mm,Customizable

Shaft Diameter: 20mm--210mm,Customizable

Stroke Length: 30mm--14000mm,Customizable

Color: Customizable

Application: Packing Machinery

Minimum Order:1 Pieces

Supply Ability:1500 Pieces/ Month

Overview:

hydraulic cylinders are used in a variety of industries, including packing machines. They are used to provide the force needed to move components of the machine, such as the conveyor belt, the packing head, and the sealing unit.

Features:

-Heavy duty: Designed for use in demanding applications, such as steel mills.

-High pressure: Rated for 16MPa of pressure.

-Long lasting: Can operate for long periods at full load.

-Low maintenance: Easy to disassemble and service.

-Highly efficient: Provides long life and high productivity.

-Meets international safety standards.

-Wide range of options: Available in a variety of sizes, configurations, and materials.

-Customizable: This can be customized to meet specific application requirements.

Product Design:

hydraulic cylinders for packing machines are typically made of steel or aluminum. The cylinder body is typically made of a strong,

durable material that can withstand the forces involved in the packing process. The piston is typically made of a material that can resist wear and tear.

The design of a hydraulic cylinder for a packing machine will vary depending on the specific application.

For example, a cylinder for a conveyor belt will need to be designed to provide the force needed to move the belt at a constant speed.

A cylinder for a packing head will need to be designed to provide the force needed to seal the product accurately.

Working Principle:

Hydraulic cylinders work by using the force of pressurized fluid. The fluid is pumped into the cylinder, which causes the piston to move.

When the fluid is released, the piston moves back to its original position.

The force of the fluid is determined by the pressure of the fluid and the cross-sectional area of the piston. The higher the pressure, the greater the force.

The larger the cross-sectional area, the less force is required to move the piston.

Detail photos:

Application:

Food and beverage: Hydraulic cylinders are used to move conveyor belts, packing heads, and sealing units in food and beverage packaging machines.

They are also used to apply pressure to packages to ensure that they are sealed tightly.

Pharmaceuticals: Hydraulic cylinders are used to move components of pharmaceutical packaging machines, such as blister packs, bottles, and cartons.

They are also used to apply pressure to packages to ensure that they are tamper-evident.

Cosmetics: Hydraulic cylinders are used to move components of cosmetic packaging machines, such as tubes, bottles, and jars.

They are also used to apply pressure to packages to ensure that they are sealed tightly.

Chemicals: Hydraulic cylinders are used to move components of chemical packaging machines, such as drums, totes, and bags.

They are also used to apply pressure to packages to ensure that they are sealed tightly.

Industrial: Hydraulic cylinders are used to move components of industrial packaging machines, such as pallets, boxes, and containers.

They are also used to apply pressure to packages to ensure that they are properly secured.

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

Speak to one of our experts today to learn more about our products solutions.